The New Product Development Design Process: From Concept to Production

Costs. Timeline. Quality. Functionality. Durability. These are commonly the first topics that come up when we engage with customers on a new product development and design. We have worked across multiple industries on the full product lifecycle and all of them share the same steps.

Phase 1: Product Concept

Value engineering creates a road-map for a good idea to become an excellent product. Together, we analyze your ideas, gather information to define functions and analyze costs. We will then create options for advanced product enhancement and incorporate considerations such as design for manufacturing (DFM) and define KPIs for value analysis. This is also the time when we explore efficiencies in both circuit design and components to create a comprehensive path forward.

An inexpensive micro controller can add dozens of additional features to a product without increasing cost.

Phase 2: Product Design

After an analysis of cost versus function we can advance your idea into the design phase and begin designing the PCB layout and solutions for your product.

The emphasis on DFM is heightened during this phase, and component availability heavily influences the requirements. Schematic designs include a thorough review of availability on all circuit parts and electronic sub-assemblies. This simplifies supply chain management allowing continuous and on-time delivery.

Some of the electronic circuit design software and resources we use during this phase include:

- Product Design Value = Function ÷ Cost

- Altium Designer

- Auto CAD Inventor

- Embedded Software

- PCB Layout

- 3D Rendering

- Programmable In-circuit Micro Processors

Although many of our designs are specific for individual customers, our experience allows us to “cut and paste” ideas from previous designs using commonality of proven concepts and reducing new inventory requirements.

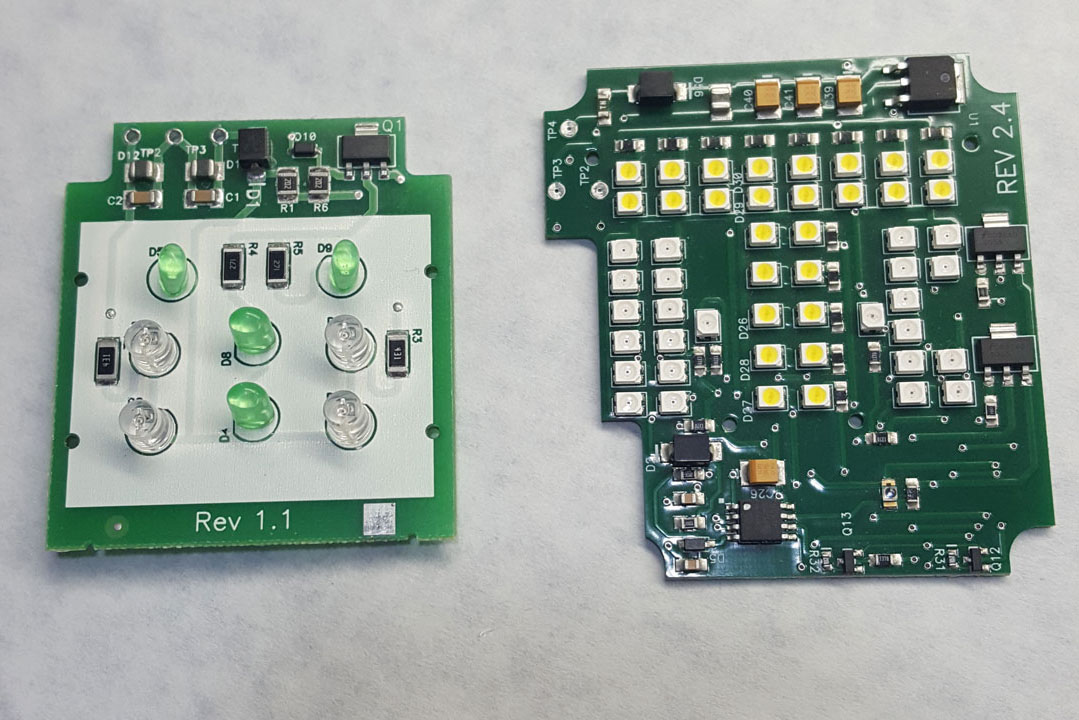

Phase 3: Product Prototyping

Following the final engineering review we will produce sample products for hardware/software testing, assembly process verification, quality monitoring, and agency approvals.

Prototypes are manufactured in-house, offering a seamless transition into full-scale production. We produce custom tooling and test fixtures to control cost and reduce lead-time. Our production staff and engineering staff work closely together to ensure our prototype meets your initial specifications and has been designed for manufacturability.

- Process Design

- Software Design

- Tooling

- Fixtures

- Automated Test

- Work Instructions

In-circuit programming offers flexibility for prototyping embedded software.

Phase 4: Product Production

Once production begins, our vertically integrated manufacturing system will produce your assembly on-time and to the highest quality standards you should expect from any electronic product manufacturer. Through automation and continuous process improvement we will reduce lead times, increase quality and control costs on your line. Through the project and into product maintenance and even future redesign of NextGen solutions, our management team will stay committed to making your supply chain more efficient.

- SMT Placement

- Wire Harnesses

- Plastics

- CNC Machining

- Coatings

- Encapsulations

Value engineering processes reduce both time to market and cost.

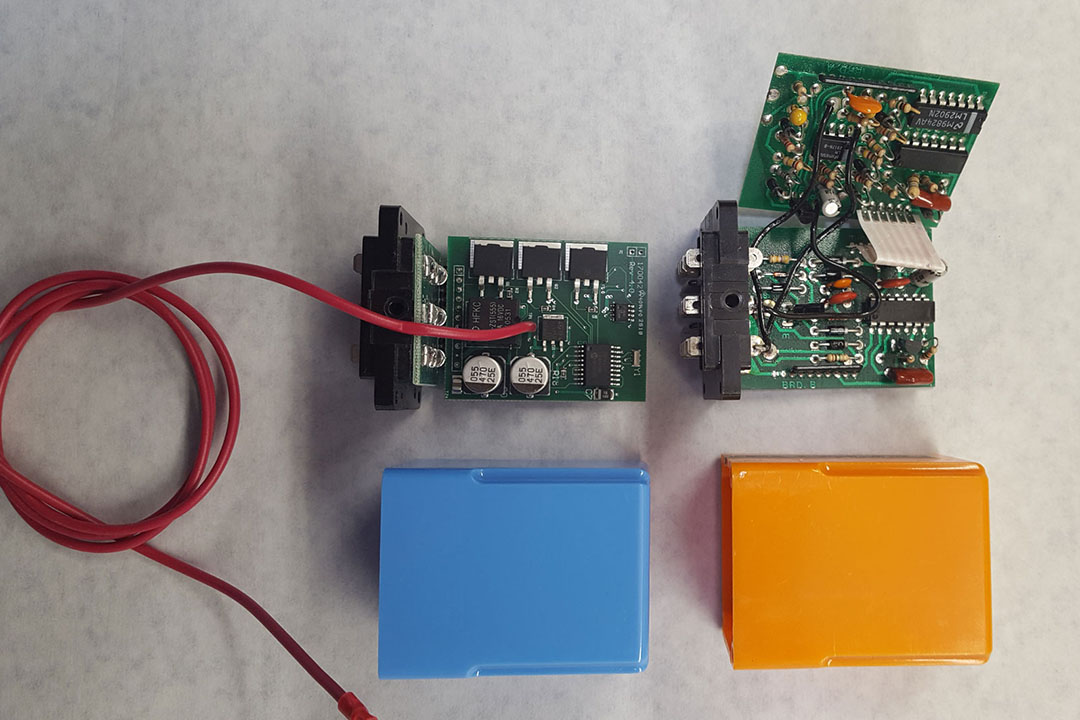

NextGen Solutions: Modernize to Monetize

Over the years, customers have trusted us time and time again to design solutions that replace obsolete parts, improve performance in their existing applications, and audit systems to be more profitable. We’ve helped many OEMs manage component obsolescence and design NextGen solutions. Be our next customer to rediscover value through modernization of your existing designs. Let us help you update your application for the 21st century.

Obsolete Parts Management in NextGen Production

Managing for the advances in technology means actively managing part obsolescence. Given the fast-moving nature of technology today, you’re bound to have obsolete parts in your assembly sooner or later.

At VeraTech, we understand what how obsolete parts can affect production. We work hard to mitigate the disruption to production by taking a proactive approach to managing for part obsolescence. Accommodating next generation production takes keen planning before, through and post-production. Often times it requires coming up with a creative and sustainable solution, quickly. Proper planning and proactive component part management means you can trust we’ll find you a solution, ideally before it becomes an issue.

We are also on the watch for cost savings for your components. If you’re taking advantage of our fully integrated supply chain for new product development, you’re already getting the best value for your parts at a fraction of the cost. However, when it comes to getting the best value for the best price, all of our customers benefit from our years of component management experience.